Specifications

Surface Treatments

Certifications

- ISO 9001 - 2015 Certified

- PED 2014/68/EC

- NACE MR0175/ISO 15156-2

- NORSOK M-650

- DFAR

- MERKBLATT AD 2000 W2/W7/W10

Alloy A286 Hex Bolts, also known as super alloy A-286, contains iron-nickel-chromium with additions of Molybdenum and Titanium. TorqBolt Inc. stocks a wide range of A286 products utilized in high-temperature conditions in various industries, such as Offshore, Oil & Gas, Building, Aerospace, and Automotive Industry. The Alloy A286 feature impeccable characteristics of excellent fabrication, good machinability, good oxidation resistance, high creep-rupture strength, and high corrosion resistance. While the experts recommend no use of this alloy in Sulfur acid environments, these alloys provide oxidation resistance up to 1500°F (815°C). These acidic environments are generally found in the high-temperature exhaust streams. Call us for inquiries!

| Nickel | 24.0-27.0 |

|---|---|

| Iron | Balance* |

| Chromium | 13.5-16.0 |

| Titanium | 1.90-2.35 |

| Molybdenum | 1.0-1.5 |

| Vanadium | 0.10-0.50 |

| Carbon | 0.08 max. |

| Manganese | 2 max. |

| Silicon | 1 max. |

| Aluminum | 0.35 max. |

| Sulfur | 0.03 max. |

| Boron | 0.001-0.01 |

| MECHANICAL & PHYSICAL PROPERTIES | 21°C | 93°C | 204°C | 427°C | 537.8°C | 649°C | 760°C |

|---|---|---|---|---|---|---|---|

| Coefficient of Thermal Expansion µm/m°C | - | 16.6 | - | 17.3 | 17.6 | 17.8 | 18.5 |

| Modulus of Elasticity / x105 MPa | - | - | - | - | 1.65 | 1.52 | 1.59 |

| Ultimate Tensile Strength/ MPa | 999.7 | - | 986 | 951.5 | 903.2 | 710.2 | 441.3 |

| 0.2% Yield Strength/ MPa | 655 | - | 641.2 | 641.2 | 599.8 | 606.7 | 427.5 |

| Elongation % | 24 | - | 21 | 18 | 18 | 13 | 18 |

| Thermal Conductivity kcal/(hr.m.°C) | - | 11.9 | - | 14.6 | 19.3 | 21 | - |

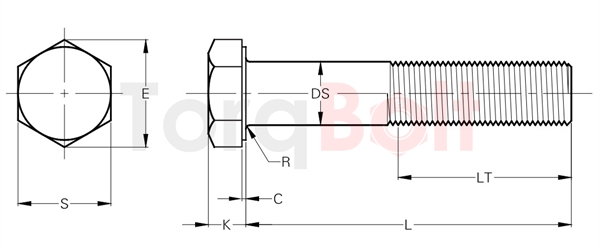

| NOM. THREAD DIAMETER (d) | THREAD PITCH (coarse) | a max. | washer | e min. | k | Max. = Nom. Dimensions | s | |||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Nom. Dimensions | min. | max. | min. | |||||

| M3 | 0.5 | 1.5 | 0.15 | 0.4 | 6.01 | 2 | 1.88 | 2.12 | 5.5 | 5.32 |

| M4 | 0.7 | 2.1 | 0.15 | 0.4 | 7.66 | 2.8 | 2.68 | 2.92 | 7 | 6.78 |

| M5 | 0.8 | 2.4 | 0.15 | 0.5 | 8.79 | 3.5 | 3.35 | 3.65 | 8 | 7.78 |

| M6 | 1 | 3 | 0.15 | 0.5 | 11.05 | 4 | 3.85 | 4.15 | 10 | 9.78 |

| (M7) | 1 | 3 | 0.15 | 0.5 | 12.12 | 4.8 | 4.65 | 4.95 | 11 | 10.73 |

| M8 | 1.25 | 3.75 | 0.15 | 0.6 | 14.38 | 5.3 | 5.15 | 5.45 | 13 | 12.73 |

| M10 | 1.5 | 4.5 | 0.15 | 0.6 | 18.9 | 6.4 | 6.22 | 6.56 | 17 | 16.73 |

| M12 | 1.75 | 5.25 | 0.15 | 0.6 | 21.1 | 7.5 | 7.32 | 7.68 | 19 | 18.67 |

| M14 | 2 | 6 | 0.15 | 0.6 | 24.49 | 8.8 | 8.62 | 8.98 | 22 | 21.67 |

| M16 | 2 | 6 | 0.2 | 0.8 | 26.75 | 10 | 9.82 | 10.18 | 24 | 23.67 |

| (M18) | 2.5 | 7.5 | 0.2 | 0.8 | 30.14 | 11.5 | 11.28 | 11.72 | 27 | 26.67 |

| M20 | 2.5 | 7.5 | 0.2 | 0.8 | 33.53 | 12.5 | 12.28 | 12.72 | 30 | 29.67 |

| (M22) | 2.5 | 7.5 | 0.2 | 0.8 | 35.72 | 14 | 13.78 | 14.22 | 32 | 31.61 |

| M24 | 3 | 9 | 0.2 | 0.8 | 39.98 | 15 | 14.78 | 15.22 | 36 | 35.38 |

| (M27) | 3 | 9 | 0.2 | 0.8 | 45.2 | 17 | 16.65 | 17.35 | 41 | 40 |

| M30 | 3.5 | 10.5 | 0.2 | 0.8 | 50.85 | 18.7 | 18.28 | 19.12 | 46 | 45 |

| (M33) | 3.5 | 10.5 | 0.2 | 0.8 | 55.37 | 21 | 20.58 | 21.42 | 50 | 49 |

| M36 | 4 | 12 | 0.2 | 0.8 | 60.79 | 22.5 | 22.08 | 22.92 | 55 | 53.8 |

| (M39) | 4 | 12 | 0.3 | 1 | 66.44 | 25 | 24.58 | 25.43 | 60 | 58.8 |

| M42 | 4.5 | 13.5 | 0.3 | 1 | 71.3 | 26 | 25.58 | 26.42 | 65 | 63.1 |

| (M45) | 4.5 | 13.5 | 0.3 | 1 | 76.95 | 28 | 27.58 | 28.42 | 70 | 68.1 |

| M48 | 5 | 15 | 0.3 | 1 | 82.6 | 30 | 29.58 | 30.42 | 75 | 73.1 |

| NOM. THREAD DIAMETER (d) | THREAD PITCH (coarse) | a | washer | face | e min. | Nom. Dimensions | K | max. | s | |

|---|---|---|---|---|---|---|---|---|---|---|

| max. | min. | max. | min. | max. | min. | |||||

| M3 | 0.5 | 1.5 | 0.15 | 0.4 | 6.01 | 2 | 1.88 | 2.12 | 5.5 | 5.32 |

| M4 | 0.7 | 2.1 | 0.15 | 0.4 | 7.66 | 2.8 | 2.68 | 2.92 | 7 | 6.78 |

| M5 | 0.8 | 2.4 | 0.15 | 0.5 | 8.79 | 3.5 | 3.35 | 3.65 | 8 | 7.78 |

| M6 | 1 | 3 | 0.15 | 0.5 | 11.05 | 4 | 3.85 | 4.15 | 10 | 9.78 |

| M8 | 1.25 | 3.75 | 0.15 | 0.6 | 14.38 | 5.3 | 5.15 | 5.45 | 13 | 12.73 |

| M10 | 1.5 | 4.5 | 0.15 | 0.6 | 17.77 | 6.4 | 6.22 | 6.58 | 16 | 15.73 |

| M12 | 1.75 | 5.25 | 0.15 | 0.6 | 20.03 | 7.5 | 7.32 | 7.68 | 18 | 17.73 |

| M14 | 2 | 6 | 0.15 | 0.6 | 23.35 | 8.8 | 8.62 | 8.98 | 21 | 20.67 |

| M16 | 2 | 6 | 0.2 | 0.8 | 26.75 | 10 | 9.82 | 10.18 | 24 | 23.67 |

| M20 | 2.5 | 7.5 | 0.2 | 0.8 | 33.53 | 12.5 | 12.28 | 12.72 | 30 | 29.67 |

| M24 | 3 | 9 | 0.2 | 0.8 | 39.98 | 15 | 14.78 | 15.22 | 36 | 35.38 |

| M30 | 3.5 | 10.5 | 0.2 | 0.8 | 50.85 | 18.7 | 18.28 | 19.12 | 46 | 45 |

| M36 | 4 | 12 | 0.2 | 0.8 | 60.79 | 22.5 | 22.08 | 22.92 | 55 | 53.8 |