Specifications

Surface Treatments

Certifications

- ISO 9001 - 2015 Certified

- PED 2014/68/EC

- NACE MR0175/ISO 15156-2

- NORSOK M-650

- DFAR

- MERKBLATT AD 2000 W2/W7/W10

At TorqBolt Inc., we specialize in offering the Alloy A286 Cap Screws that are known for their high tensile strength, oxidation resistance, and creep resistance at elevated temperatures. This iron-based austenitic material with its age-hardenability activates the ultimate strength for rugged applications in various industries. Though not ideal, their oxidation resistance proves effective even in high-temperature exhaust stream conditions of up to 1300°F (700°C). With the additions of Molybdenum and Titanium, this Iron-Nickel-Chromium material stocks its performance for typical applications in Oil & Gas, Automotive, Power Generation, Offshore, and Aerospace Industry. We lead the list of top cap screw suppliers in India and Abroad.

| Nickel | 24.0-27.0 |

|---|---|

| Iron | Balance* |

| Chromium | 13.5-16.0 |

| Titanium | 1.90-2.35 |

| Molybdenum | 1.0-1.5 |

| Vanadium | 0.10-0.50 |

| Carbon | 0.08 max. |

| Manganese | 2 max. |

| Silicon | 1 max. |

| Aluminum | 0.35 max. |

| Sulfur | 0.03 max. |

| Boron | 0.001-0.01 |

| Temp | Ultimate Tensile Strength | 0.2% Yield Strength | Elong in 2″ | Reduction of Area | Charpy V-notch |

|---|---|---|---|---|---|

| °F | psi | psi | % | % | ft-lb |

| RT* | 95,000* | 50,000* | 40* | - | - |

| RT | 145000 | 95000 | 24 | 43 | - |

| 400 | 143000 | 93000 | 21 | 53 | 59 |

| 800 | 138000 | 93000 | 18 | 35 | 51 |

| 1000 | 131000 | 87000 | 18 | 31 | 45 |

| 1200 | 103000 | 88000 | 13 | 14 | 35 |

| 1400 | 64000 | 62000 | 18 | 23 | - |

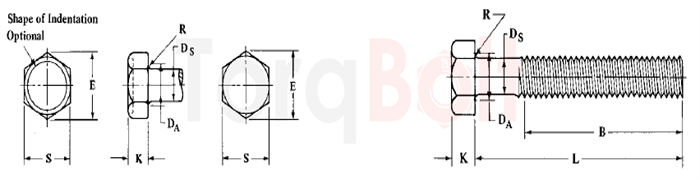

| Nominal Screw Size and Thread Pitch | DS | DK | Ea | K | DA | R | |||

|---|---|---|---|---|---|---|---|---|---|

| Body Diameter | Hex Width Across Flats | Hex Width Across Corners | Head Height | Underhead Fillet | |||||

| Transition Dia | Radius | ||||||||

| Max | Min | Max | Min | Min | Max | Min | Max | Min | |

| M2×0.4 | 2.00 | 1.65 | 3.20 | 3.02 | 3.38 | 1.6 | 1.3 | 2.6 | 0.1 |

| M2.5×0.45 | 2.50 | 2.12 | 4.00 | 3.82 | 4.28 | 2.1 | 1.8 | 3.1 | 0.1 |

| M3×0.5 | 3.00 | 2.58 | 5.00 | 4.82 | 5.40 | 2.3 | 2.0 | 3.6 | 0.1 |

| M3.5×0.6 | 3.50 | 3.00 | 5.50 | 5.32 | 5.96 | 2.6 | 2.3 | 4.1 | 0.1 |

| M4×0.7 | 4.00 | 3.43 | 7.00 | 6.78 | 7.59 | 3.0 | 2.6 | 4.7 | 0.2 |

| M5×0.8 | 5.00 | 4.36 | 8.00 | 7.78 | 8.71 | 3.8 | 3.3 | 5.7 | 0.2 |

| M6×1 | 6.00 | 5.21 | 10.00 | 9.78 | 10.95 | 4.7 | 4.1 | 6.8 | 0.3 |

| M8×1.25 | 8.00 | 7.04 | 13.00 | 12.73 | 14.26 | 6.0 | 5.2 | 9.2 | 0.4 |

| M10×1.5 | 10.00 | 8.86 | 16.00 | 15.73 | 17.62 | 7.5 | 6.5 | 11.2 | 0.4 |

| M12×1.75 | 12.00 | 10.68 | 18.00 | 17.73 | 19.86 | 9.0 | 7.8 | 13.2 | 0.4 |

| M10×1.5b | 10.00 | 8.86 | 15.00 | 14.73 | 16.50 | 7.5 | 6.5 | 11.2 | 0.4 |